Expert Digitizing for Embroidery: Rapid and Reliable Service

Expert Digitizing for Embroidery: Rapid and Reliable Service

Blog Article

Grasping the Needlework Digitizing Refine: Your Ultimate Overview

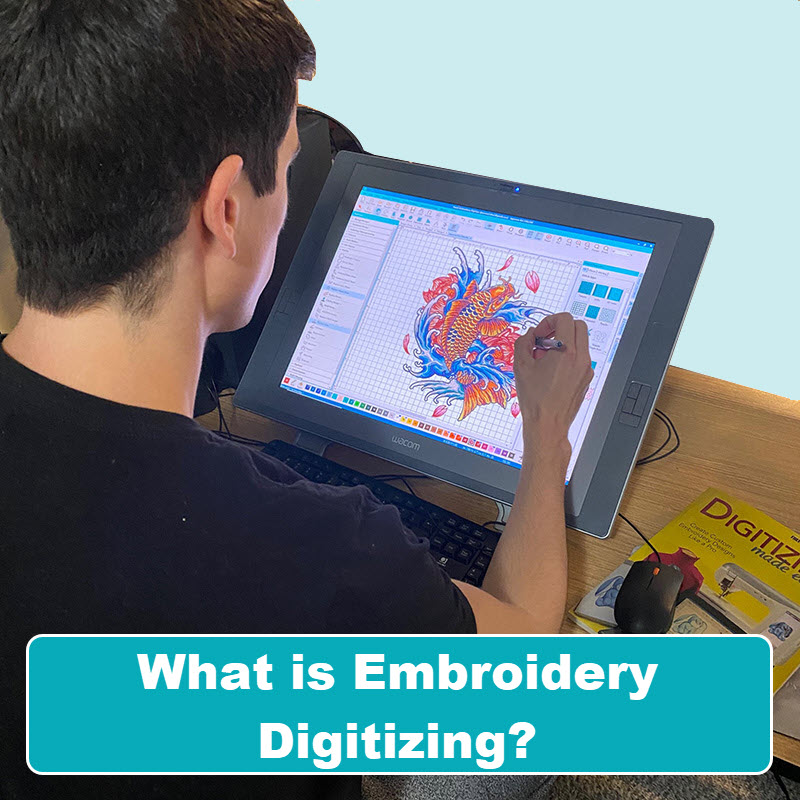

Needlework digitizing is a precise craft that requires accuracy and know-how to translate intricate designs right into electronic layouts for machine needlework. As craftsmens start this journey to grasp the needlework digitizing process, a thorough understanding of the essentials establishes the foundation for quality. Beyond the fundamental understanding lies a world of sophisticated software application, specialized tools, and nuanced techniques waiting to be checked out. By delving into the nuances of digitizing, one can open a world of creative possibilities and boost their needlework projects to new heights.

Understanding Needlework Digitizing Essentials

Needlework digitizing basics create the structure upon which intricate designs are equated into machine-readable formats for exact sewing. This preliminary action in the needlework digitizing process is critical for making sure that the final embroidered item is a devoted depiction of the initial design. Understanding needlework digitizing basics entails realizing key principles such as stitch kinds, sew direction, density, underlay, and pull settlement.

Sew kinds play an important function in determining the visual and textural result of the embroidered layout. By selecting the proper stitch kind, whether it be satin, fill, or running stitch, digitizers can achieve the desired effect and boost the total quality of the embroidery. Additionally, stitch instructions influences the flow and dimension of the style, while density determines the spacing and insurance coverage of the stitches.

Moreover, padding sewing supplies security to the style by securing the textile and stopping distortion throughout the embroidery procedure. Draw compensation is another crucial factor to consider to counteract the natural propensity of textile to contract when sewn. Understanding these embroidery digitizing essentials is fundamental for developing professional-quality embroidered products.

Choosing the Right Digitizing Software

Selecting the proper digitizing software program is an essential decision that considerably influences the efficiency and quality of the needlework digitizing process. Digitizing for Embroidery. When picking the best digitizing software program, it is vital to consider elements such as the intricacy of layouts you prepare to produce, the user-friendliness of the software program, the level of client assistance supplied, and the compatibility with your embroidery equipment

There are various digitizing software program options readily available out there, ranging from fundamental programs for newbies to innovative software for specialist digitizers. Some preferred options consist of Wilcom EmbroideryStudio, Hatch Embroidery Software Application, and PulseID. These software provide a vast array of tools and functions to assist you create intricate layouts with ease.

Prior to choosing, it is advisable to discover the various software program alternatives through free trials or trials to determine which one ideal suits your requirements. In addition, checking out evaluations and looking for recommendations from knowledgeable digitizers can give important understandings into the strengths and weaknesses of each software (Digitizing for Embroidery). By meticulously evaluating your demands and comparing the features of various digitizing software, you can make an educated choice that enhances your needlework digitizing process

Digitizing Devices and Techniques

Optimizing Design Settings for Embroidery

Mastering the complexities of design settings is fundamental in achieving optimal results in the needlework digitizing procedure, structure upon the structure laid by comprehending digitizing tools and methods. When enhancing design settings for embroidery, it is vital to consider elements such as stitch type, density, padding, draw settlement, and enrollment. Sew type choice affects the overall appearance and feeling of the layout, with alternatives like satin, fill, and running stitches offering different structures and results. Thickness describes the spacing and density of stitches, impacting the style's insurance coverage and longevity. Correct rug stitching gives security and avoids textile distortion, specifically for complicated designs or on elastic materials. Pull settlement changes for fabric stretch throughout stitching, ensuring exact design duplication. Registration setups line up different aspects of the design properly, preserving overall style integrity. By fine-tuning these layout settings, embroiderers can boost the high quality and accuracy of their embroidered productions.

Troubleshooting Common Digitizing Issues

When encountering usual digitizing concerns throughout the embroidery procedure, it is vital to recognize the root triggers and implement efficient remedies quickly. One usual issue is stitch thickness issues, where stitches might be also dense, triggering the fabric to tighten, or too sparse, causing gaps in the style. Readjusting the stitch density settings in the digitizing software program can help solve this concern.

Another frequent obstacle is thread breaks during the embroidery procedure. This can take place as a result of various reasons such as inaccurate stress setups, boring needles, or making use of low-grade string. Making certain appropriate upkeep of the embroidery maker, consisting of normal needle modifications and stress modifications, can lessen the event of thread breaks.

In addition, design enrollment mistakes can result in misaligned aspects within the embroidery style. Examining the design positioning in the digitizing software program and making essential changes prior to sewing can help in preventing this concern. By addressing these common digitizing problems immediately and properly, you can make certain a smoother embroidery procedure and high-quality completed items.

Verdict

To conclude, understanding the needlework digitizing process requires a solid understanding of the essentials, the appropriate selection of software application, and understanding of tools and techniques. Maximizing design setups and repairing usual digitizing problems are vital action in guaranteeing top quality needlework outcomes. By adhering to these steps diligently, one can attain accuracy and performance in the digitizing procedure.

Report this page